¶ Why Steel?

A standard PrintNC uses hollow structural section (HSS) steel tubing for the frame. Prototype designs used aluminum extrusion but were replaced with steel for its increased performance.

¶ Stiffness

Stiffness is the resistance of a material to deform under load. This is incredibly important to CNC applications, where your machining quality relies on the minimization of frame deformation (i.e. maximizing rigidity). Thankfully, steel ALWAYS has roughly the same stiffness (±5%), regardless of any heat treatment or alloy.

Steel is about 3x as stiff as aluminum of equal dimensions.

Strength is the amount of load the material can take before permanent deformation (yield strength) or failure (ultimate strength). Strength varies significantly between metals, alloys, and heat treatments. However, your frame should never permanently deform or break. Therefore, strength is not a property that should concern your buying decisions. High strength steel will not yield performance gains.

¶ Weight

Steel is about 2.5x as dense as aluminum. Weight damps vibrations and can result in parts with better surface finish.

¶ Price and Availability

Structural steel is inexpensive, resulting in an incredibly high stiffness/cost ratio. It is also easily purchasable from a local supplier in your area with minimal lead times.

¶ PrintNC steel

The PrintNC design is parametric, meaning it will adjust to many sizes of steel.

¶ Steel needed

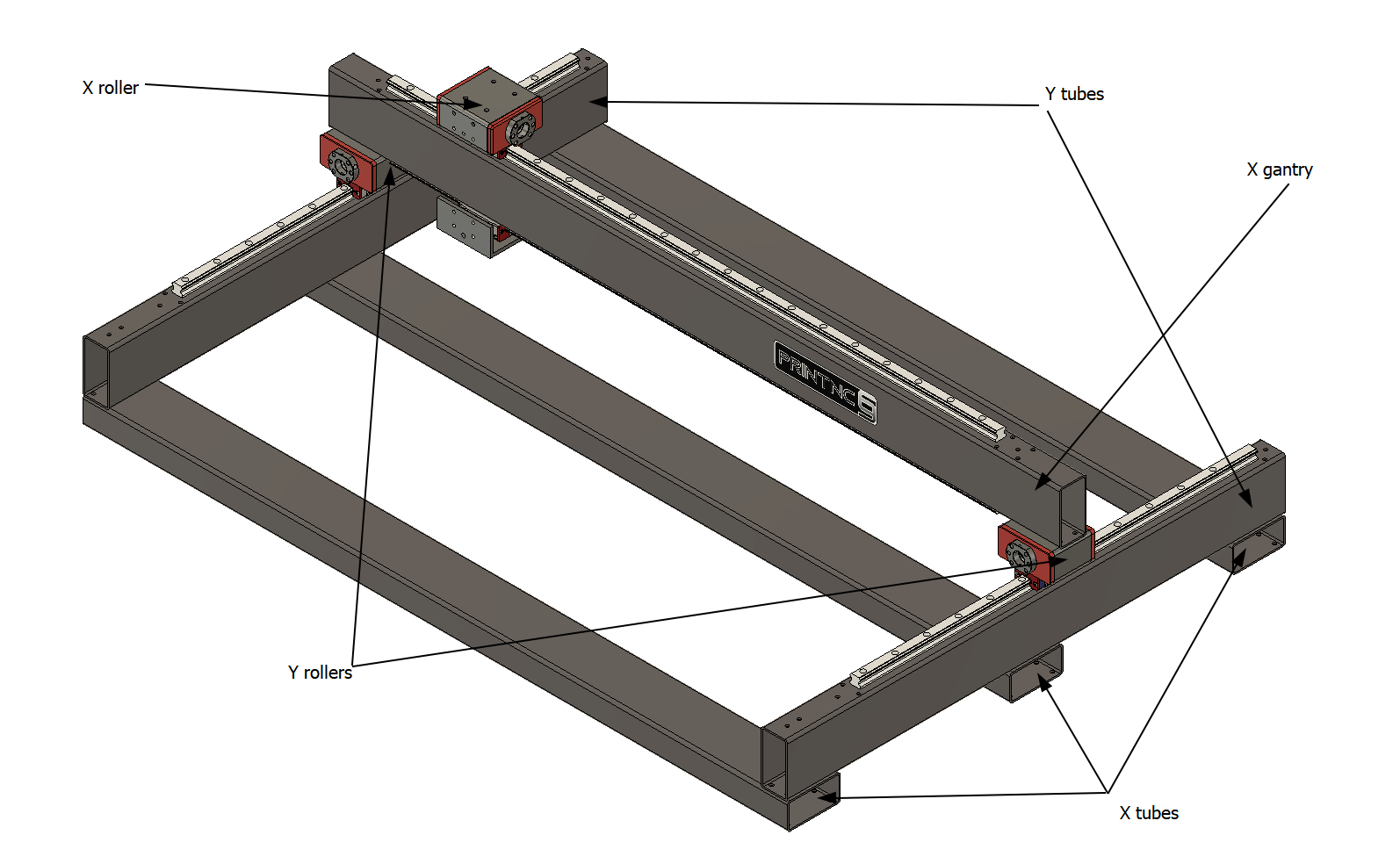

|

The PrintNC will need several beams for the build :

|

|

¶ Steel naming convention

Steel tubes are always defined using 3 figures. For example : 75 mm x 50 mm x 3 mm

¶ “long” side

The “long” side is always the highest value (in our example, 75 mm). It's also called “width".

¶ "short" side

The “short” side is always the lowest value (in our example, 50 mm). It's also called “height”.

¶ thickness

Finally, the last figure is always representing the thickness.

¶ Steel tubes dimension

The default choice is 75 mm x 50 mm x 3 mm (3" x 2" x 0.12") Hot Rolled Steel Tubing (A513 preferable).

Keep in mind, steel tubes have tolerances: T <= 5 mm: +/- 10 % → so you may end up with only 2.7mm instead of the desired 3mm→ 4mm is probably the better choice.

Some builders have chosen larger dimensions for increased rigidity, extra Z clearance, or simply availability.

Here's a list of steel tubes that can be used for the PrintNC :

¶ Metric units

- 75 mm x 50 mm

- 80 mm x 50 mm

- 80 mm x 60 mm

- 100 mm x 50 mm

You can select a thickness of 3 mm, 4 mm or 5 mm for all those tube dimensions.

¶ Imperial units

- 2" x 3"

- 2" x 4"

You can select a thickness of 0.12 or 0.178 for all those tube dimensions.

¶ Steel fillet radius

¶ Definition

Each steel tube has a fillet at the intersection of two faces. This fillet has a specific radius, dependent of the thickness of the tube.

You'll need to know the fillet radius to correctly print all 3D printed parts. You can use this tool to discover it.

¶ Radius concerns

Be careful not selecting steel tube 5 mm (0.178") thickness or above, for the short tubing sections (X roller and Y rollers).

Steel tubing generally increases bending radius when increasing wall thickness. With a large enough radius, design issues will start to arise in some of the steel sections.

If you buy 50 mm x 75 mm (2x3") tube with a thickness above 5 mm (0.178"), you'll need to buy small amount of tubes in thickness lower than 4.5 mm, for both the Y and X rollers.

Larger cross section steel might not have this issue.

¶ Consequences of increased height/width

¶ Increased height / short side

| Advantages | Disadvantages |

|---|---|

| Additional Z clearance. | Decreases rigidity by increased lever on spindle |

| Increased gantry stiffness |

¶ Increased Width / long side

| Advantages | Disadvantages |

|---|---|

| Additional Z clearance. | Decreases rigidity by increased lever on spindle |

¶ Tall, Wide, Thick, Thin.. How Should I Modify my Steel for Maximum Rigidity

Before making any purchases, size your build and make the suggested adjustments to maintain adequate rigidity. However, remind that rigidity rapidly decreases when increasing gantry (x dimension) length.

¶ Thickness

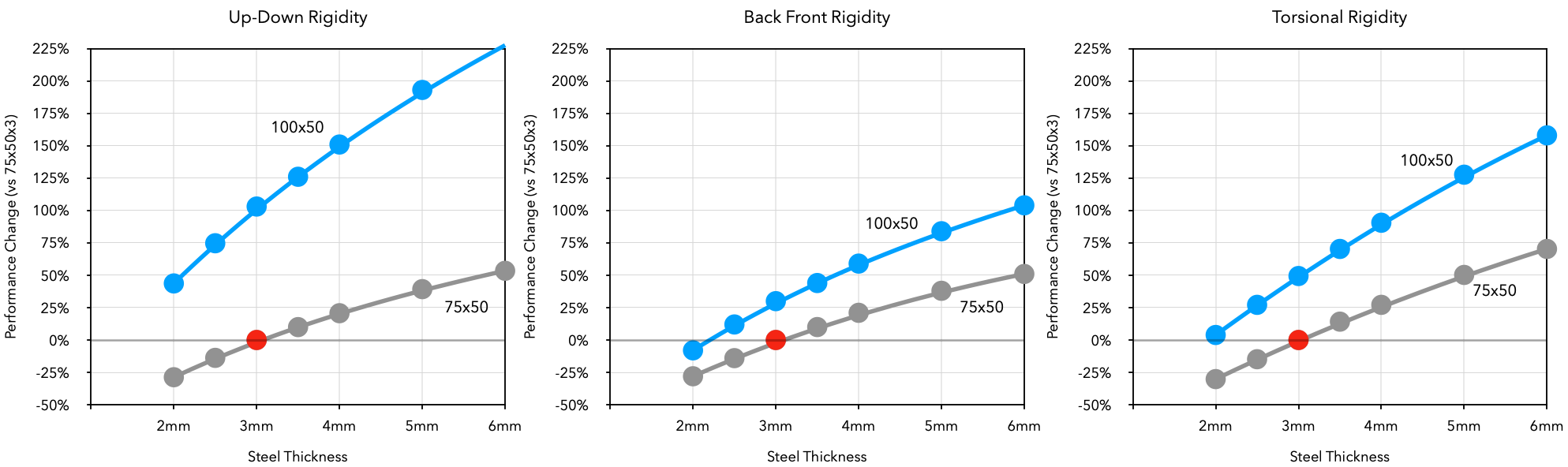

Buying thicker steel will increase the rigidity of your machine and increase weight.

¶ Stiffness Comparison

It is worth noting, however, that there are many more points of deformation in a CNC frame that play a large role. Therefore, do not expect a 50% stiffer frame by simply increasing wall thickness from 3 to 5mm. This requires simulations to solve.

There are also downsides to increasing thickness. For example, increasing mass will also increase inertia. You may notice a decrease in maximum deceleration/acceleration. In addition, design issues come into effect when increasing thickness above 4.5 mm (0.178") as discussed in the section above.

Sources : Stiffness Improvements Over 3mm Tubing, Rectangular Tube Section Calculator

¶ In-Depth steel details

If you want to know more about steel and its standard, heads up to this page !