¶ In-Depth steel details

¶ Hot vs. Cold Rolled Steel

Hot and Cold Rolling are types of forming your steel, named by the steel's temperature during the process. Typically cold rolled steel has sharper edges, less millscale and is more expensive then hot rolled. Both types are good for the PrintNC and it can be chosen by availability as in many regions of the world only one of them is easily available.

¶ Other Terminology

Stainless is a family of alloy that naturally resists corrosion. It is expensive and very difficult to drill.

Galvanization is a surface finish process applied to many types of steel to resist corrosion. Nevertheless, suppliers sell them as distinct categories.

¶ Standards

For tubing, the ‘standard’ that the steel is produced to combines both chemical composition and manufacturing tolerances. Do not get caught up on chemical composition. Anything will work.

Shape Tolerance.. Values calculated for 3mm thickness

| Standard | Radius | Straightness | Squareness | Twist | Convexity/Concavity | Thickness | Dimensions |

| AS/NZS 1163 | ? | 0.15% of total length | 90°±1° | 2mm+0.5mm/m in length | Max. 0.8% or 0.5mm, whichever is greater | ||

| ASTM A500 |

≤3T ≤ 9.14 ( 0.36") |

1/8" x length (in feet) divided by 5 ≤0.075" | 90° ± 2° |

2.1mm/m (0.075" /3') |

±0.635 (±.0.025") |

± 10% | ± .025" |

| ASTM A513 | 3.175(0.125") ≤ R ≤ 5.55(0.21875") | ≤0.0625" | 90° ±0.018" |

2.1mm/m (0.075" /3') |

±0.381 (±0.015") |

||

| CSA G40.21-98 | ≤ 6.8(0.268") | 1/8" x length (in feet) divided by 5 ≤0.075" | 90° ± 2.0° | 0.21mm/m (0.075" /3') | ? | +10% / -5% | ± .030" |

| EN 10219 |

1.6T≤R≤2.4T 4.8≤R≤7.2 |

0.15% of total length and 3.0mm over any 1m length | 90° ±1° | 2.0mm + 0.5mm/m | ≤0.8% (0.5mm min) | ± 10% | ±1% with min of ±0.5% |

| EN 10210-2 | ? | 0.2% of total length and 3.0mm over any 1m length | 90° ±1° | 2mm + 0.5mm/m | 1% | ||

| EN 10305-5 |

T≤2.5mm: R≤1.5T T>2.5mm: R≤2.2T |

0.15% of total length and 3.0mm over any 1m length | 90° ±1° | min(B, H) / 10 | Within straightness tolerance | ± 10% and ± 0.35mm |

¶ AS/NZS

| AS/NZS 1163 | |

|---|---|

| Convexity/Concavity | Max. 0.8% or 0.5mm, whichever is greater |

| Radius | ? |

| Twist (per 3') | 2mm+0.5mm/m in length |

| Squareness | 90°±1° |

| Straightness (per 3') | 0.15% of total length |

Sources: AS/NZS 1163

¶ ASTM

| A500 | A513 | |

|---|---|---|

| Convexity/Concavity | ±.0.025" | ±0.015" |

| Radius | ≤0.36" | 0.125" ≤ r ≤ 0.21875" |

| Twist (per 3') | 0.075" | 0.075" |

| Squareness | 90° ± 2° | 90° ±0.018" |

| Straightness (per 3') | ≤0.075" | ≤0.0625" |

¶ CSA

| CSA G40.20-04 | |

|---|---|

| Convexity/Concavity | ? |

| Radius | 0.268" |

| Twist (per 3') | 0.075" |

| Squareness |

90° ± 1.0°

|

| Straightness (per 3') | 1/8in. / 1feet length (10.4mm/1m length) |

Sources: CSA G40.20-04, CSA G40.21-98

¶ EN

| EN 10219 | EN 10210-2 |

EN 10305-5 |

|

|---|---|---|---|

| Convexity/Concavity | ≤0.8% (0.5mm min) | 1% | Within straightness tolerance |

| Radius | 1.6T≤R≤2.4T | ? |

T≤2.5mm: R≤1.5T T>2.5mm: R≤2.2T |

| Twist | 2.0mm + 0.5mm/m | 2mm + 0.5mm/m | min(B, H) / 10 |

| Squareness | 90° ±1° | 90° ±1° | 90° ±1° |

| Straightness | 0.15% of total length and 3.0mm over any 1m length | 0.2% of total length and 3.0mm over any 1m length | 0.15% of total length and 3.0mm over any 1m length |

¶ Steel characteristics

¶ Flatness and Straightness

|

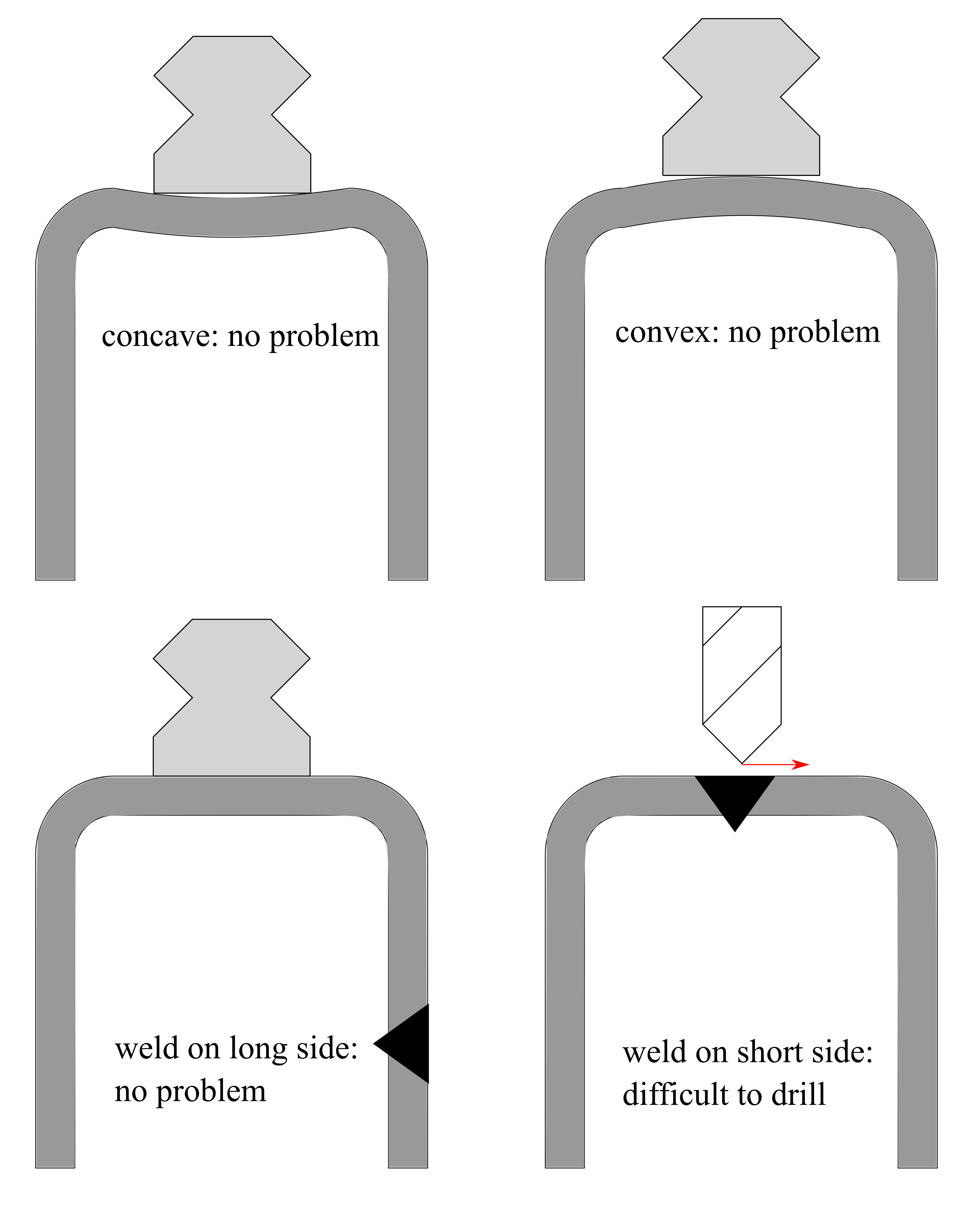

Due to processing techniques, hot rolled steel will have have inconsistencies with flatness and straightness. However, most PrintNC machines built to date have used hot rolled steel without any concerns. Cold rolled steel can be used as an alternative if this is a concern for you. HGR Rails and carriages are by design are quite tolerant of inconsistencies in the mounting surface and mounting accuracy. It's one of the main reason this hardware has been selected for the PrintNC. HIWIN spec for HGR20 rail allows for 0.13mm of variation in the mounting surface while still remaining within the design and performance specifications for long term reliability in high duty cycle commercial environment at maximum load. HGR20 rails are also vastly over-specified for the gantry weight and any cutting forces that the PNC generates so we are working at the bottom end of their performance envelope which extends service life and reliability. See this document for more information about HGR rails specifications. Steel tubes can also show slight convex or concave curvatures on some faces, but it doesn't impact the PrintNC design in any way. |

|

¶ Corrosion Resistance

Galvanization is a coating process used to prevent corrosion. It will not provide performance benefits, but is an easy rust prevention solution if you don't plan on painting your steel.

Hot and Cold Rolled steel can be treated through oil, dry coats, and painting to prevent rust formation. Guides to painting can be found here.

¶ Wall Thickness

3mm wall thickness is cost effective, stiff enough, and thick enough to thread into. However, deflection under load increases with the size of your machine. Therefore, you may want to increase wall thickness for a large build. The added mass will also have a damping effect but it is unclear how big of a role it plays

¶ Flattening Steel

Flattening the steel, although typically unnecessary, is a frequently discussed topic. Options are milling and Blanchard grinding or self-leveling epoxy.