¶ Summary

Add the mechanical parts to the Y axis.

¶ Prep

¶ Hardware Needed:

- mallet or hammer with a soft buffer, or spare piece of wood

- Assembled and prepared frame from section 6

- (2) Assembled Y-Axis Roller from previous step

- (2) BF12 (the thinner floating bearing block)

- (2) BK12 (the thicker fixed bearing block)

- (2) Ball screw with attached nut

- (10) M6x30mm bolts

- (12) M6x50mm bolts

- (12) M5x110mm bolts or M5 threaded rod

- (8) M5x20 socket head bolts for mounting motor to motor mount

- (2) motors

- (2) couplers

- drill

- tool to mark ~6mm

- 5 mm drill bit

- M6 tap bit

- (2) zerk fittings for ballscrews

- Circlip/C-Clip pliers - needed for attaching the circlip to the BF12 end of the ball screws.

- 2mm hex wrench for the set screw in the retainer nut.

¶ Printed Parts Needed

- (2) BK12 Mount

- (2) Ball Screw Face Plate Front

- (2) Ball Screw Face Plate Rear

- (2) Motor mount

¶ When complete, verify

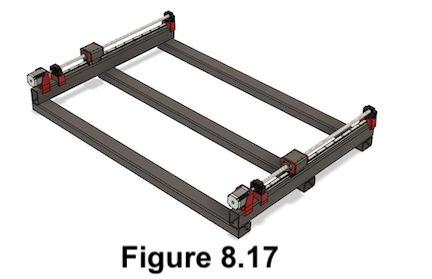

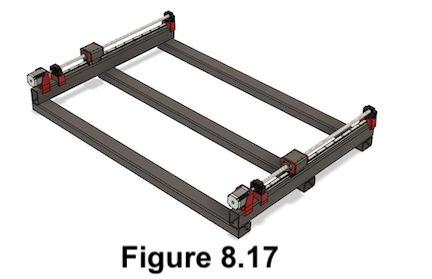

- It should look like this:

¶ Build Steps:

-

Ensure the assembled frame has two BF12 mounts and both HGR20 rails installed. The BK12 mount should not be installed as it will block the HGW20 block from being installed onto the rails. The frame should look like Figure 8.1.

-

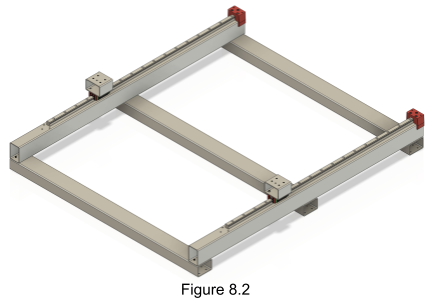

Gently install both of the assembled Y-Axis rollers onto the HGR20 rail as shown in Figure 8.2. Their location on the rail does not yet matter. Note: The zerk fitting should go on the opposite side from the ballscrew nut for easier access which means towards the BF12 mounts.

-

Loosen the wiper screws of each HGW20 block while on the rail, and gently roll the block along the length of the rail to allow the wiper to self align. Then tighten the wiper screws up. This will drastically improve their performance.

-

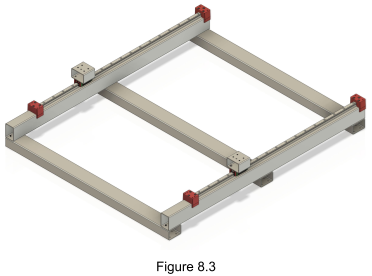

Install both BK12 Mounts onto the tapped holes created in step 6 using M6x30mm bolts as shown in Figure 8.3.

-

Add a zerk fitting to each ball screw nut and add grease.

-

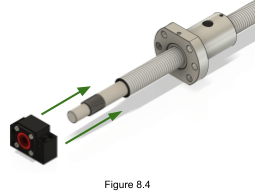

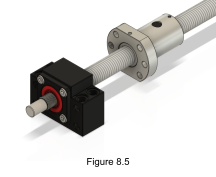

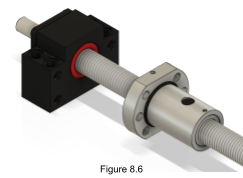

Insert a ball screw into a BK12 block, oriented as shown in Figures 8.4, 8.5, and 8.6.

NEW for V4 - The orientation of the BK12/15 block is the opposite direction to match the HM12/15 design

The protruding cover plate needs to face the end of the ballscrew where the motor coupler will be attached later. Check that both spacer rings are sitting in the bearing block, one from each side. You will likely need to lubricate both the ball screw and the bearing inside the BK12. Then, gently “persuade” the BK12 on. The manufacturer suggests first sliding it over the threaded portion of the screw, then banging the bottom of the screw on a piece of wood, allowing the BK12 to move itself down the ball screw without use of a mallet. Be very careful to maintain proper alignment as the low tolerances mean any misalignment will cause the parts to jam and become damaged.

-

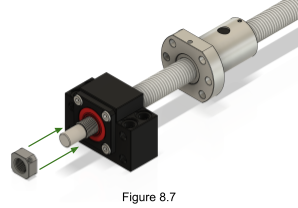

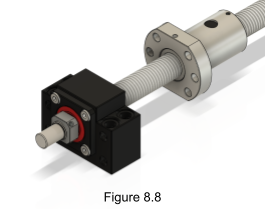

Screw the retainer nut onto the ball screw behind the BK12 as shown in Figure 8.7 and 8.8. Ensure it is securely tightened against the BK12.

-

Tighten the set screw in the retainer nut so the retainer nut can no longer move.

-

Move the ball screw nut close to the BK12.

-

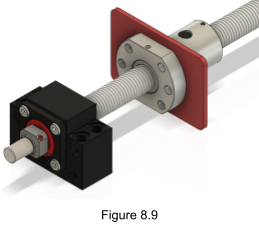

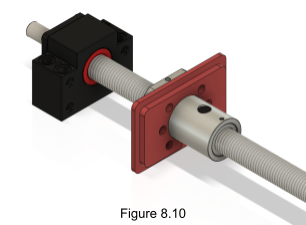

Place the Ball Screw Face Plate Front directly behind the ball screw nut as shown in Figures 8.9 and 8.10.

-

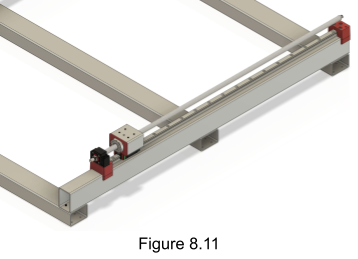

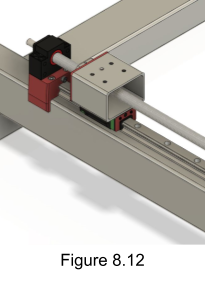

Pass the empty end of the ball screw through one of the Y-Axis roller beams, the result should look like Figure 8.11 and 8.12.

-

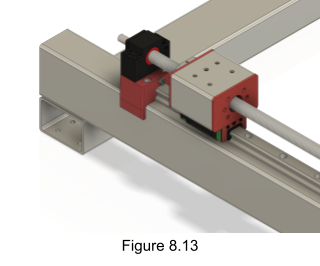

Pass the inset face of the Ball Screw Face Plate Rear over the unused side of the ball screw and slide it all the way up the screw. Insert the inset side of the printed part into the Y-Axis roller beam as shown in Figure 8.13.

-

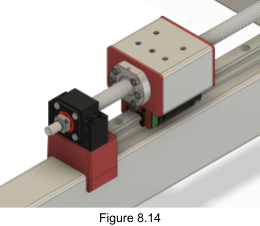

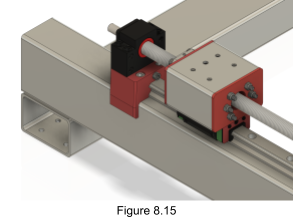

Attach the ball screw nut to the Y-Axis roller assembly using M5x110mm bolts passing the bolts all the way through both printed plates and M5 nuts on the other side as shown in Figure 8.14 and 8.15. If you are using a metal ballscrew plate, you may need to shim the ball screw nut if your roller tube is not cut perpendicular.

If shimming is needed, make a note of it and come back to it after the mechanical assembly steps are complete. This will save you time in not doing the shimming more than once.

-

Finally install a BF12 onto the empty end of the ball screw and fasten into place using the circlip that was included with the BF12.

-

Repeat previous 9 steps with other ball screw.

NOTE: If you used PLA for the printed mounts be careful to screw the bolts in slowly so as not not cause the plastic to melt around the thread due to friction. To avoid this, you may wish to pre-thread the printed parts with a tap bit or by preinstalling an M6 bolt and removing it.

-

Install both BF12s onto their mounts using M6x50mm bolts. These screw directly into the plastic.

-

Install both BK12s onto their mounts using M6x50mm bolts. These screw directly into the plastic.

-

Bring the Y-Axis rollers as close as possible to the BK12 end of the rail as shown in Figure 8.16.

-

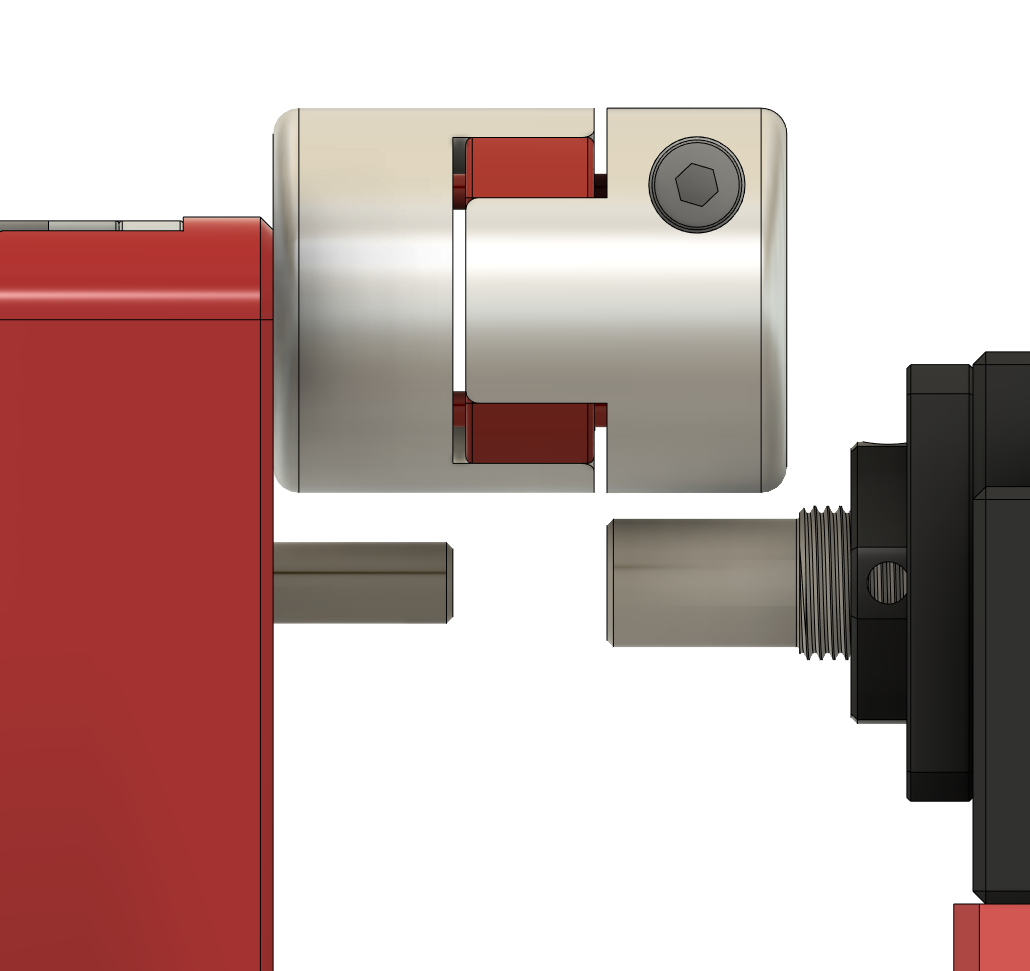

Position the motor mount on the X-Frame. You can find the distance to the BK12 block by holding the motor temporarily to the motor mount. The distance between the motor shaft and the ball screw should be as large as the red dampening element in the coupler.

-

Mark the holes of the motor mount with your ~6 mm diameter marking tool as before with the BK12 Mount.

-

Drill the marked points with a 5 mm drill bit and tap with a M6 tap bit.

-

Fasten the motor mounts to the beams with M6x30 socket head bolts.

-

Attach the coupler to the motor and the ball screw on each side.

-

Fasten the motor to the motor mount using M5x20 socket head bolts with nuts. It should look something like Figure 8.17.