¶ Sizing your Build

With the beta release of PrintNC V4, information on this page may be out of date. If you would like to build a V4 machine, please read this page and then check the discord for any clarification while we catch up with documentation.

¶ Sizing PrintNC V4

All PrintNC machines are capable of cutting wood, aluminium (and non-ferrous metals) and some steels. As machine size increases, rigidity decreases, so you need to customise your machine to have a work area that is big enough to support the projects you would like to complete, but not so large that rigidity is compromised for the materials you'd like to cut.

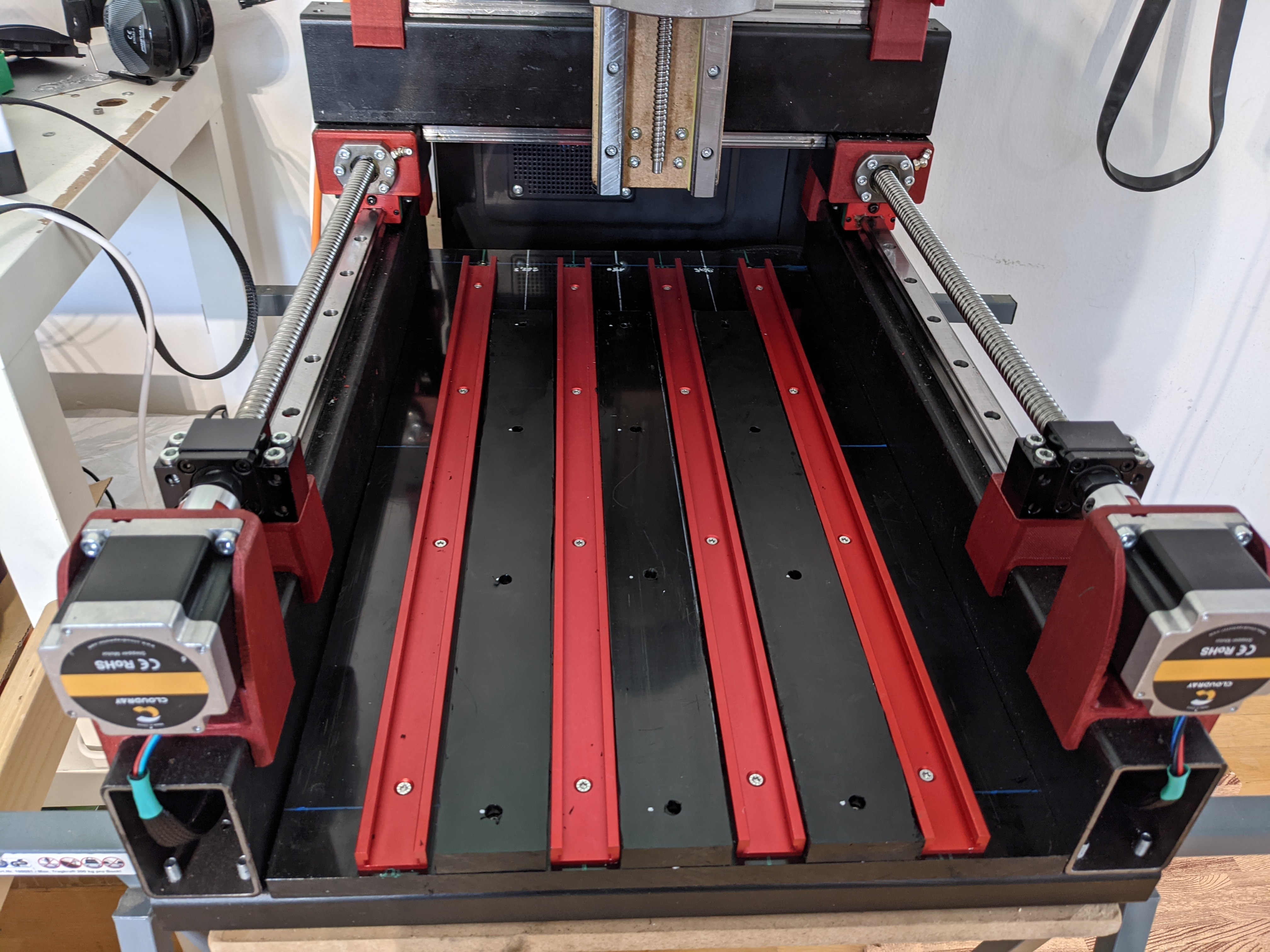

PrintNC V4 is designed around three standard variations which can be customised to your individual needs. In order of increasing work area: Desktop, Metalcutter, Woodcutter.

Desktop: Ideally 300x300mm to 575x575mm cutting area. The smaller tubing starts to be a bit too flexible for much larger than that, though you can create a "hybrid" using 50x75mm gantry tubing for slightly larger X, maybe up to 800mm cutting area.

Metalcutter: Uses dual-carriages on all axes and larger rails and steel than the desktop, and is better for aluminum focused machines. Sized from 600x600 to 1000x1000mm cutting area to minimize gantry flex. Longer than that is recommended going very large gantry steel, 100x75mm.

Woodcutter: Woodcutter is basically PrintNC V3 with refinements. Single carriages, with a full sheet width cutting area for those wanting to complete tiled projects in plywood. Woodcutter can still cut aluminum just fine, it'll just take more time and effort to get nice surface finishes and tolerances.

¶ Estimated Work Area

The default PrintNC V4 has an approximate work area of 25x25" or 625x625mm for metalcutter preset and 50x25" or 1275x625mm for woodcutter preset. However, the design can be scaled up or down with minimal modification. There is a frame and rail BOM script available for the V4 CAD here https://github.com/interias/PrintNC-BOM-Generator

¶ Sizing Considerations

- The PNC is a tool. Build the tool that fits your requirements and space constraints

- Larger machine = larger projects for only a small price increase.

- Think about inserting standard size stock into your machine. e.g. maybe you want to machine out a 24"x24" piece of mdf.

¶ Going Large

Over 1500mm length gantry, increase to 4" x 2" or 100mm x 50mm steel tubes.

From 1500 to 1800mm, use 2010 ballscrew for increased rigidity to offset sag and whip from the long unsupported distance. Different printed parts are required for 2010 and are included in the PrintNC 3.0 fusion file.

Over 1800mm length, custom options are required :

- rotating nut and mid ballscrew supports

- or rack and pinion

These design options are outside the scope of the PrintNC basic design.

¶ Going Small

| The PNC can be scaled down without any difficulties. However, it is important to remember that machine price stays relatively static over a wide range of sizes. Therefore, you should not downsize unless you have reason to. Smaller build areas will limit the type of projects your machine is capable of. |

|

¶ Smallest Recommended Size

The PNC becomes more space-efficient at larger sizes. This is because about 300mm (12") of space is sacrificed to mount the stepper motors and bearing blocks. Consequentially, below 600mm (24") in the Y direction, you will only have <300mm (<12") <50% usable build length. You are better off making a moving bed system that has a constant ~50% usable area. This isn't to say it isn't possible, however.