Safety notice: If you're not experienced working with CNC spindles or endmills of the size used in a PrintNC, take care to understand the forces involved.

If you lose your grip while changing a tool, make sure your body can't come in contact with something sharp (and the tool can't come in contact with something that it will destroy (or be destroyed by.))

¶ Hardware Required

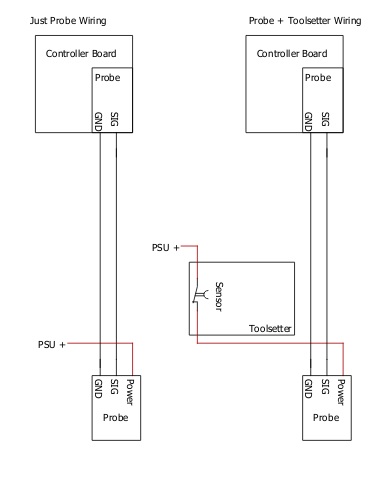

Wiring a 3 pin powered probe IE a 3d surface probe can be seen below.

PSU+ = the same positive voltage that is powering the controller board you are using. IE if using 5v, power the probe with 5v.

¶ HowTo: Semi-Automatic Toolchanges in IOSender & GRBLHAL:

- Toolsetter can be ordered here from Aliexpress here: Choose the Normally Closed type. https://www.aliexpress.com/item/1005003129746609.htm

- Connect your TLS to your Hal2k Board:

- usually there are 2 normally closed switches in the TLS, the first switch triggers immediately (used for probing) and the second switch triggers later ( the over-travel / saftey switch)

- there are 4 wires coming out, on mine green/yellow were for the probing switch, and red/black for the over-travel switch, but with a multimeter you can simply measure the continuity between cables, and the pair which looses continuity first, when pressed, is your probing switch

- the probing switch is wired to the PROBE Input on the HAL2K board, (to Sig/GND)

- the over-travel switch is wired in series with the HALT input on the HAL2K board, so pressing either the Overtravel or the HALT button (also your HALT button should be NC) should stop the machine immediately.

(Don't skip this, you inevitable crash something into the TLS, and this is a real pita to disassemble, ask me how i know)

- with the wiring done, open IOSender and confirm, that the switches are actually working, by pressing it, and checking the lights in IOSender

- ok, that's the bare minimum you need, to do some sort of tool length offset measurement.

- with this setup you can use the Probing tab in IO Sender, and probe your tools manually

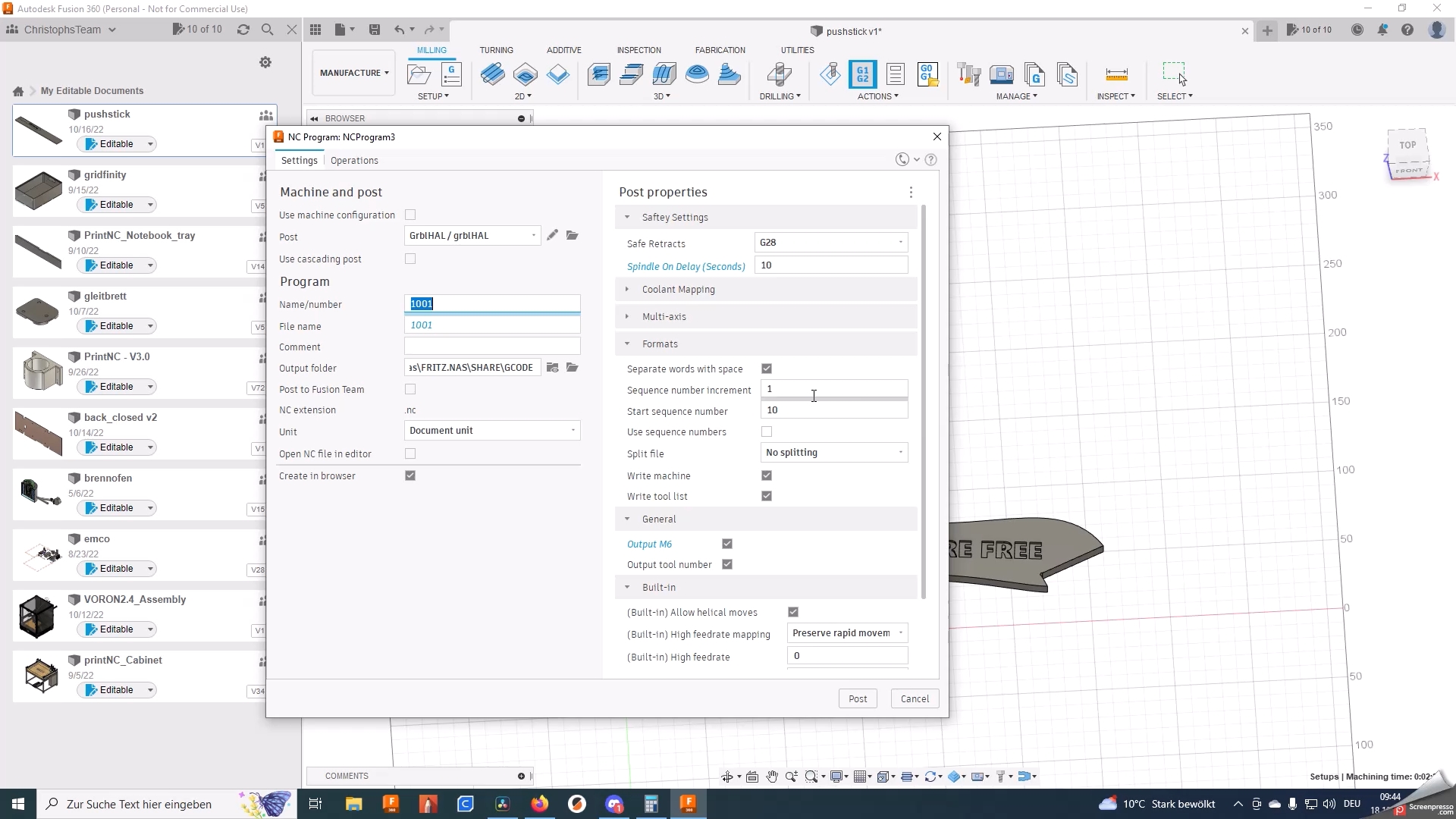

Now to the semi-automatic part, where the Controller reads the M6 Gcode and will do the Offset measurement automatically: - your Postprocessor needs to put out the M6 Gcode, in Fusion360 the GrblHAL PP is able to do this:

- double check if the generated G-Code contains the M6 command

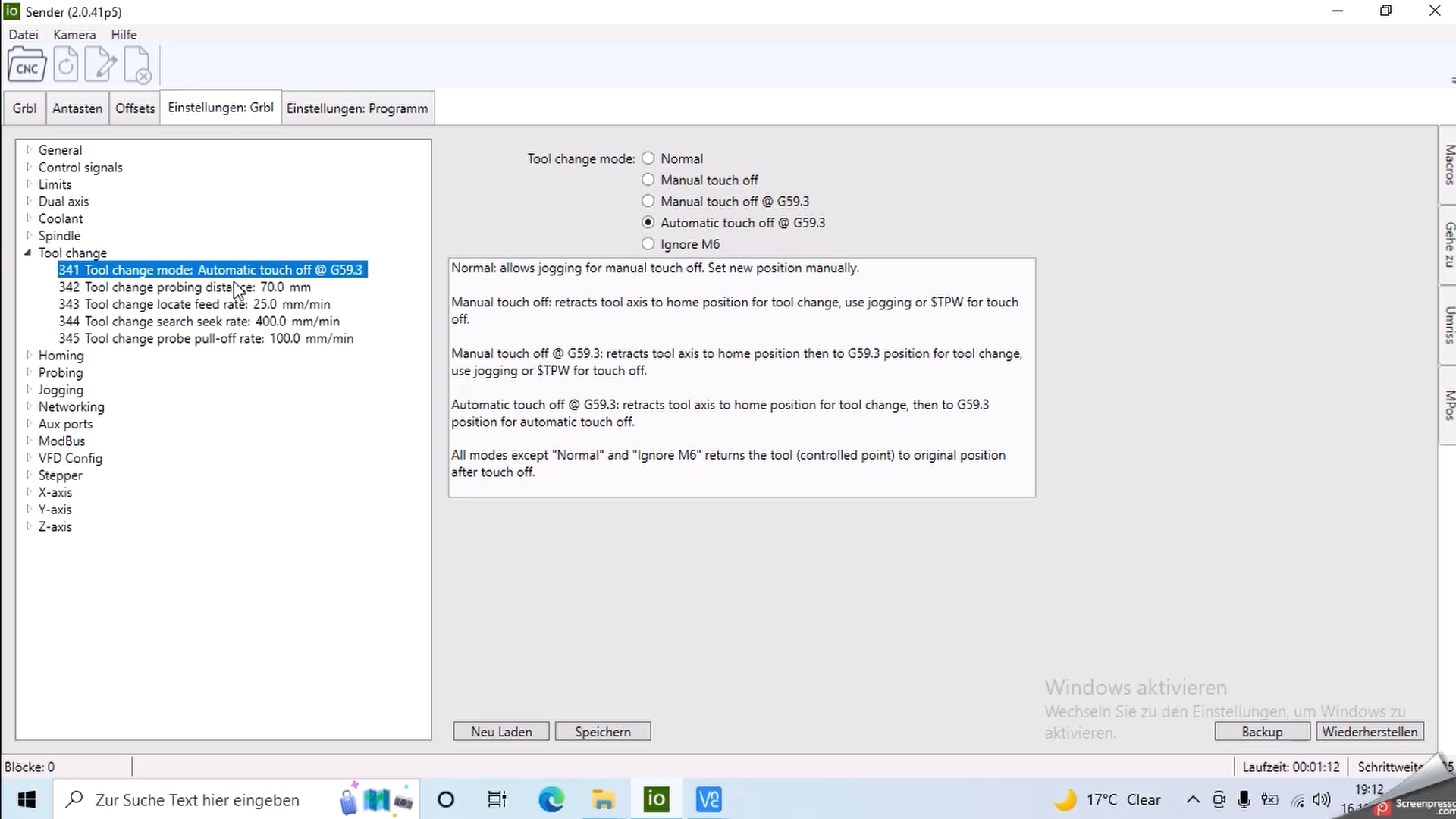

- in IOSender, you have to change these options:

- under GrblSettings: ToolChange Mode to: Automatic touch off @G59.3

- under GrblSettings: ToolChange Mode to: Automatic touch off @G59.3

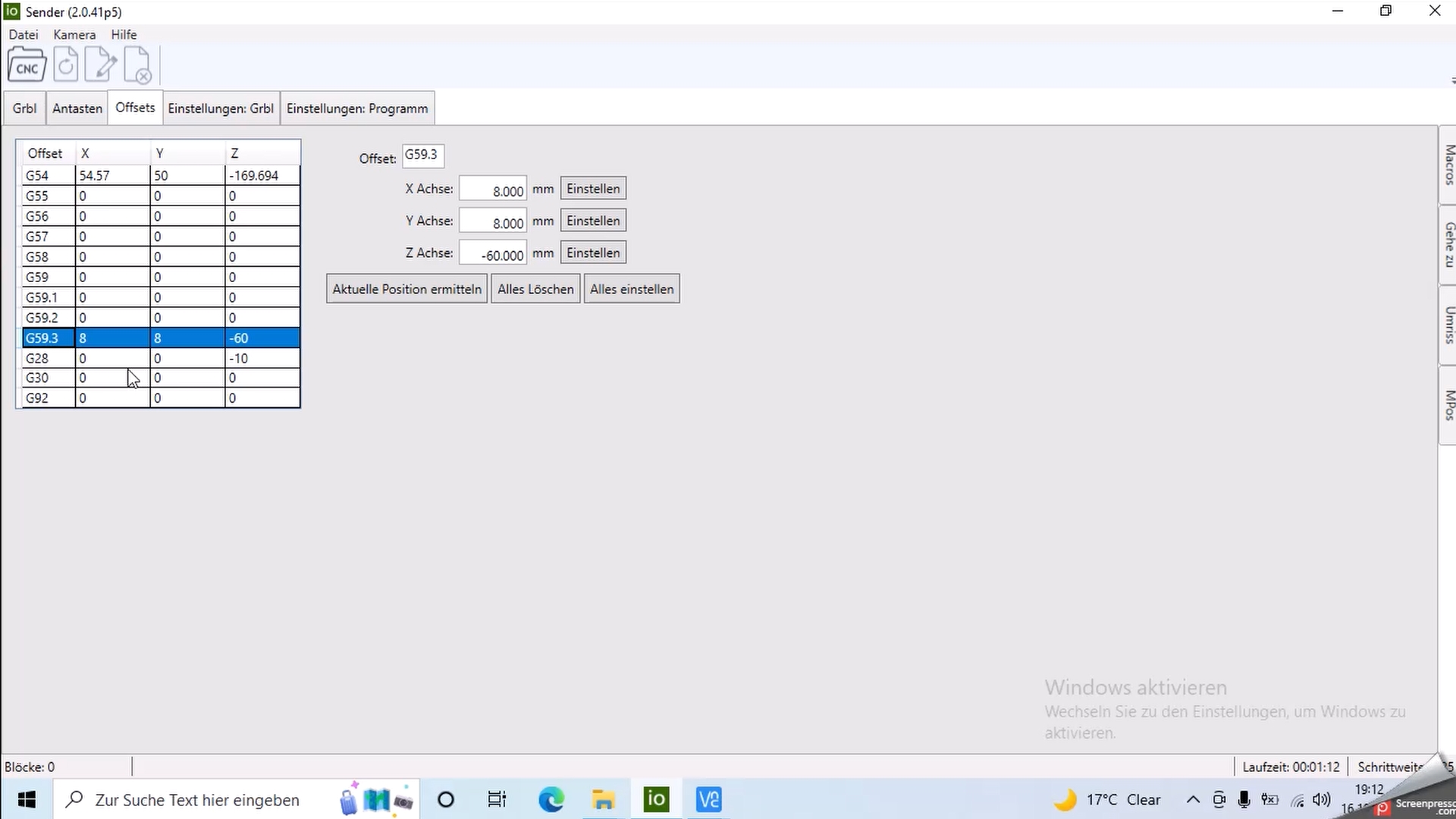

- under Offset: change the G59.3 coordinate system to the location of your Tool Length Sensor (the physical location of your TLS on the wasteboard).

your spindle will rapid to this position and from there start the seek process - You also need to change the G28 Offset, to the difference between your shortest and longest tool.

The issue is, Fusion360 will do a G28 G91 Z0 at the start of every toolpath, which drives the spindle to ZMAX. If you now insert a longer tool, and do a Tool Lenght Offset measurement, the Controller tries to put the stick of the tool, where it previously was. And since the tool is now longer, it will drive the Spindle into the Z Endstop.

to prevent this, you need to set your G28 coordinate system lower, so you have more room in the Z direction for future tool changes with longer tools.

the grblHAL PostProcessor: https://github.com/Dietz0r/grblHAL_Fusion360_Post_Processor

the Postprocess all patch: https://github.com/TimPaterson/Fusion360-Batch-Post

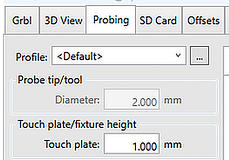

Where to set your Touch Probe/ Fixture Plate height:

Go to the Probing tab in iosender. Along the left hand side you will see a field called "Touch plate/fixture height.

Set it to the exact thickness of your touch plate.

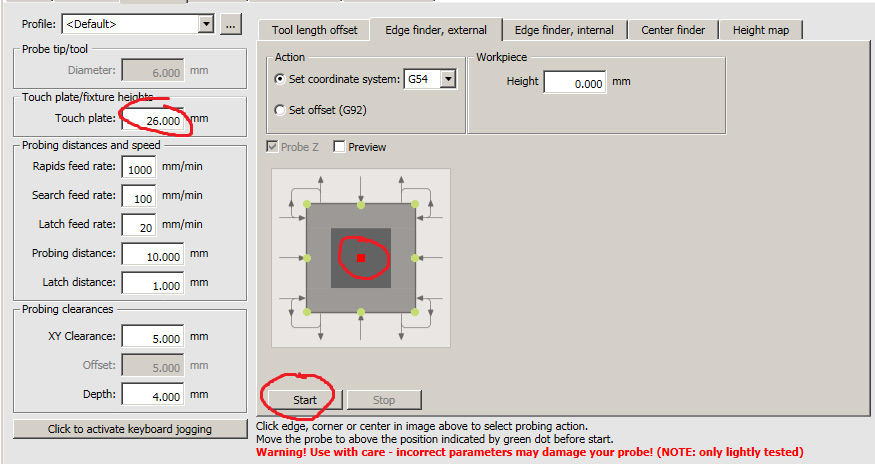

¶ Where Do I Probe for Z Height in iosender?

In order to probe your Z height in iosender you go to the Probing tab > Edge finder, external tab.

Click the top ‘edge’ of the grey graphical display to choose the top surface. Then check the Z probe checkbox.

Move your spindle tool down withing 10mm of the touch plate and then click the Start button.

iosender will take two measurements and adjust the Z zero position.

Image source and more info available here from Terjeio on gethub on probing correctly with iosender:

https://github.com/terjeio/grblHAL/discussions/197

Simplified Overview of Probing in iosender - Video by Rational:

https://youtu.be/ZBLGw8rbmtM?t=158

¶ Tool Length Sensor video by Christoph Lehner @clehn8ok

https://youtu.be/il7P6GsF4C8?t=286

Relevant settings for iosender are explained beginning at 4:45 in the video.

¶ Video of Toolchanging in ioSender/GRBLHAL

https://www.youtube.com/watch?v=GMvf2euASp8&ab_channel=DaveBullock

Here's a great tutorial article giving you a good overview of iosender to include probing:

https://www.grbl.org/single-post/one-sender-to-rule-them-all