¶ !!!!! PLEASE TEST THIS CONFIGURTION EXTENSIVELY BEFORE USING ON REAL NC CODE!!!!!

I have succesfully been able to ReMap my M6 tool change to allow for a tool touch off after each manual change to adjust the Z height without requiring a new WCS touch off or manual measurement.

You can see an example of this in work with the following videos;

https://youtu.be/rIDMpuUcoYg

https://youtu.be/6yEWJ09mp1I

If you have further questions or need clarification, you can message me on discord @kotlikm

This is an alternative to using the Probe Screen developed by Vers.by

I utilized this soultion as it seems the Probe Screen does not work easily with the use of the GMOCCAPY UI.

Minimal changes overall are required.

This is all based off the work that was openly shared on the LCNC forums seen at the following link. I made modificiations to get it working reliably as I ran into issues when using the original on the latest LCNC release.

http://www.linuxcnc.org/index.php/english/forum/10-advanced-configuration/5596-manual-tool-change--tool-lengh-touch-off?start=30#48235

At this point in time, this has been shown to work in the AXIS GUI at least once, I dont have as much experience with it, but overall should work with the use of different toolchange pins noted further along this page.

¶ BEFORE USING CHANGE THE CONFIGURATION PARAMETERS BELOW FOR YOUR MACHINE!

¶ .INI CONFIG FILE CHANGES REQUIRED

Under the [RS274NGC] section add:

change/add/use SUBROUTINE_PATH to point to the location where these tool-change subroutines are located:

[RS274NGC]

...

SUBROUTINE_PATH = macros

REMAP=M6 modalgroup=6 ngc=tool-change

REMAP=M600 modalgroup=6 ngc=tool-job-begin

Under the [EMCIO] section add:

[EMCIO]

...

TOOL_CHANGE_AT_G30 = 0

Ensure neither TOOL_CHANGE_POSITION nor TOOL_CHANGE_QUILL_UP is set.

Add the following POSTGUI_HALFILE callout

[HAL]

...

POSTGUI_HALFILE = custom_postgui.hal

¶ POSTGUI .hal FILE CREATION

Create a new file in your configuration folder called custom_postgui.hal

If you already have a postgui hal file, you can add the following lines to it, if not put the following in the newly created file

net tool-change gmoccapy.toolchange-change <= iocontrol.0.tool-change

net tool-changed gmoccapy.toolchange-changed <= iocontrol.0.tool-changed

net tool-number gmoccapy.toolchange-number <= iocontrol.0.tool-prep-number

net tool-prepare-loopback iocontrol.0.tool-prepare <= iocontrol.0.tool-prepared

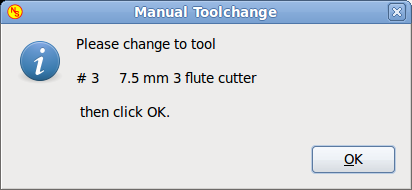

By adding these pins in your postgui, the tool change notification will reference your tool table and provide the tool description in the pop-up. This requires that you keep your tool table updated with an accurate description for the associated tool number, but i find it extremely helpful since F360 free version does not allow for setup sheets.

¶ For those using AXIS

your postgui.hal should contain the following, as AXIS does not use the detailed tool change pins the same way as GMOCCAPY

net tool-change iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-changed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

This remapping has only been tested in AXIS once that i know of, issues may occur, please reach out to me if you need help configuring.

¶ .HAL CONFIG FILE CHANGES REQUIRED

Map an input pin to be the probe input, e.g.:

net probe-in => motion.probe-input

net probe-in <= hm2_7i96.0.gpio.005.in

For multiple probe inputs, the following can be used, in this case a MESA 7i96 is controlling a NO probe, and a NC Toolsetter;

loadrt or2 count=1

addf or2.0 servo-thread

net probe-in <= hm2_7i96.0.gpio.005.in

net length-in <= hm2_7i96.0.gpio.009.in_not

net probe-in => or2.0.in0

net length-in => or2.0.in1

net probe-or-length <= or2.0.out => motion.probe-input

The following tool change pin is required as well;

loadusr -W hal_manualtoolchange

¶ .VAR FILE CHANGES REQUIRED

In your Linuxcnc.var file, ensure you have the following variables;

#5061

#5062

#5063

They can be manually added and assigned a 0.000 to start

¶ SUB ROUTINES FOLDER

Add the following sub-routines to the folder you identified in your .ini file as the SUBROUTINE_PATH

tool-job-begin.ngc

tool-change.ngc

¶ SUB ROUTINE CUSTOM SETTINGS FOR YOUR MACHINE

The following parameters will need to be set in the subroutine tool-change.ngc as appropriate for your machine configuration;

#<_UseInches> = 1.0 ( set to 1 to use inches here, or 0 to use millimeters; should match units on tool.tbl dimensions )`

#<_TravelZ> = -.25 ( machine ABS Z coordinate for travelling, typically near max Z to avoid ever hitting the work )

#<_TravelFeed> = 200.0 ( feedrate used for general Z moves when avoiding G0 )

#<_ProbeX> = 38.77 ( machine ABS X coordinate of switch/touch-off plate )

#<_ProbeY> = 25.27 ( machine ABS Y coordinate of switch/touch-off plate )

#<_ProbeFastZ> = -2.0 ( machine Z coord to move to before starting probe, longest tool should not touch switch at this Z )

#<_ProbeMinZ> = -4.75 ( machine Z coord to stop probe, shortest tool must touch switch at this Z, must be > min Z )

#<_ProbeRetract> = 0.125 ( small distance to retract before approaching switch/touch-off plate second time )

#<_ProbeFastFeed> = 100.0 ( feed rate for moving to _ProbeFastZ )

#<_ProbeFeed1> = 20.0 ( feed rate for touching switch/touch-off plate first time )

#<_ProbeFeed2> = 4.0 ( feed rate for touching switch/touch-off plate second time )

#<_ToolChangeX> = 4.0 ( machine ABS X coordinate to pause at for manual tool changing )

#<_ToolChangeY> = 1.0 ( machine ABS Y coordinate to pause at for manual tool changing )

#<_MistOnDuringProbe> = 0 ( set to 1 for mist, or 2 for coolant, or 0 for nothing during probing, to clear switch of swarf )

¶ POST PROCESSOR CHANGES REQUIRED

In addition I have had to modify the post-processor for the following (see attached .cps file for use);

- Eliminate G43 call outs after tool changes.

- Use G53 instead of G28, typically just a check box when post processing.

- Set machine home for Z in F360 machine setup to be -.250, my machine Zero is at top of travel.

¶ Post Process All

This is not required, but takes full advantage of the new setup for tool touchoff when using the free version of F360.

The following link takes you to a plugin that was developed to combine multiple tools back into a single program in F360 which was removed with the restrictions in the free version. It will also add rapids back in. I highly recommend using this post processor if you are on the free version of F360, but please use at your own risk, and thouroughly vet and test your ngc code prior to running parts.

https://github.com/TimPaterson/Fusion360-Batch-Post

¶ How to use this ReMap

M6 in the g-code will invoke a manual tool change with automatic tool height adjustment.

M600 is used at the beginning of the first g-code file of a job so that the next M6 will measure the tool for reference instead of calculating a tool length offset. It can also be invoked manually through the MDI before a job starts.

¶ My sequence of operations for Running g-code;

- Using a T99, a .250" Rod, touch off X, Y, and Z of WCS as modeled in CAM

- Manually input M600 on MDI screen

- Manually call an M6 T99, tool will touch off on toolsetter and store tool height

- Load program and run, M6 in program will prompt tool change, after changing, tool will touch off and Z will adjust

- Run any and all code using the same desired Z height for the WCS as designed

- For new WCS repeat from Step #1

¶ General theory of operation

- Touches each tool off to the tool height sensor.

- The first tool is used as the reference, all subsequent tools adjust the tool offset.

- Tool is moved away by raising Z to _TravelZ before moving towards the Tool Setter XY Coordinates, and when moving back from the switch again moves at height _TravelZ before going straight back down to the original position.

- Sets all necessary modes to ensure correct operation no matter what state the program is in when this is called. We eliminate almost all side effects by saving and restoring the modal state.